Electrified Fabric Could Zap the Coronavirus on Masks and Clothing

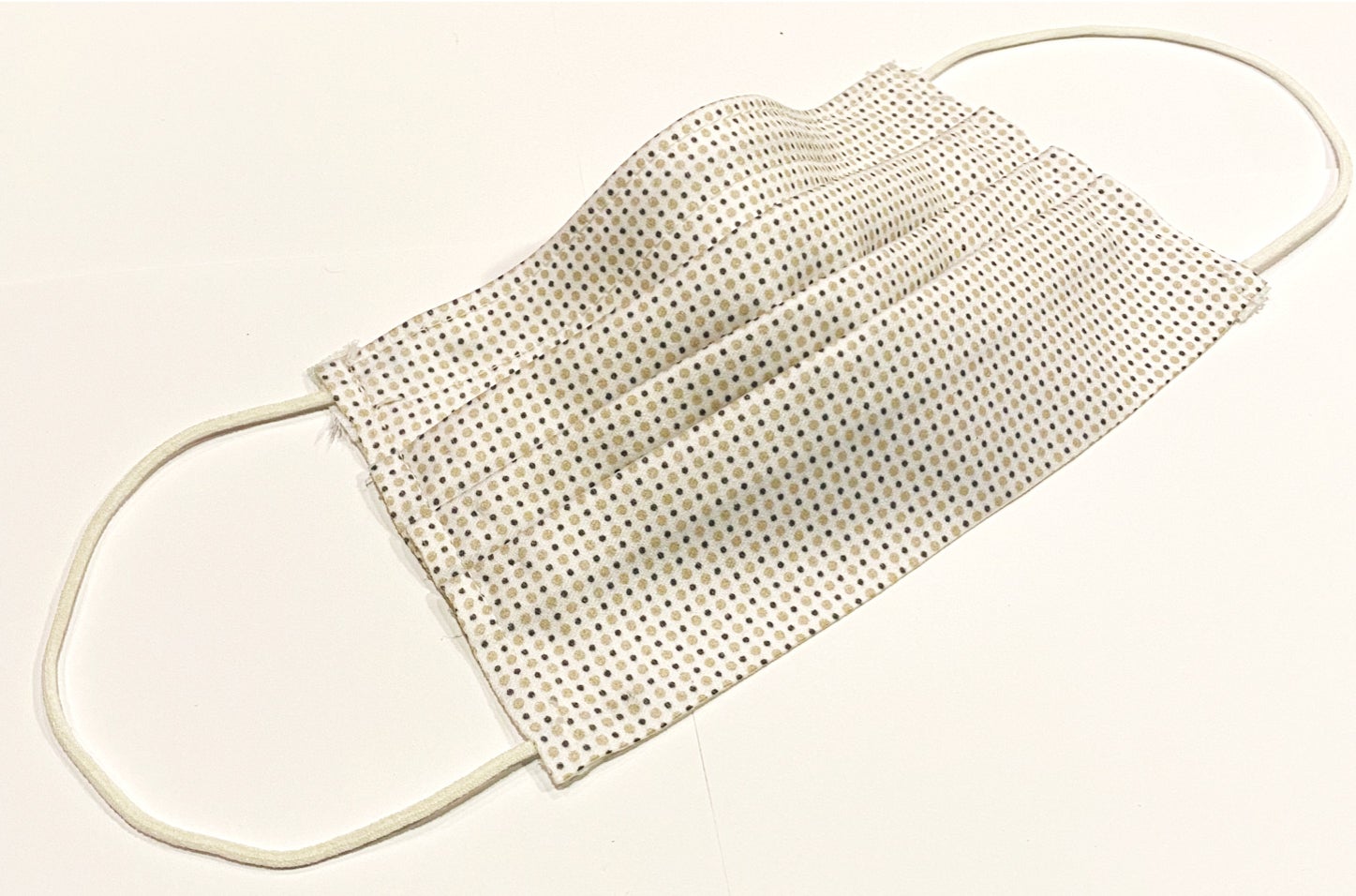

Putting on masks and other own protecting products (PPE) can slow the spread of COVID-19. The U.S. Centers for Ailment Control and Avoidance endorses anyone use some form of face covering in general public spots, in particular where social distancing is hard to sustain. And wellbeing staff are donning further coverings, these types of as gowns. Still all these types of protecting equipment shares a person substantial challenge: people today nonetheless risk getting to be contaminated with the novel coronavirus if they unintentionally contact locations of the cloth that are contaminated with viral particles. So researchers are performing to acquire cloth that could inactivate or repel coronaviruses—ideally together with the a person that leads to COVID-19—and other pathogens.

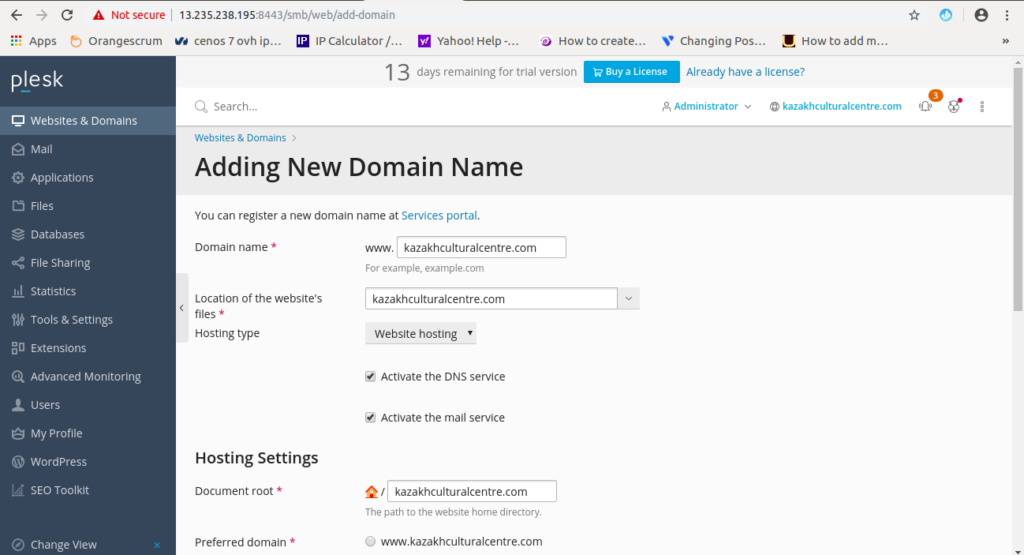

Folks can transfer infectious particles to their hands if they contact the front of a mask throughout use or when they eliminate gowns or other PPE, according to Chandan Sen, director of the Indiana Centre for Regenerative Medication and Engineering at Indiana College. He and his colleagues have been acquiring a way to render those particles and other infectious brokers harmless. The group researches “electroceutical” components that wirelessly “generate electric fields throughout the floor of the cloth,” Sen says. Individuals fields can disrupt the conduct of bacteria or viruses on the cloth.

“The magnificence of this [technological know-how] is the inherently basic layout,” he says. The polyester material is printed with alternating places of silver and zinc resembling polka dots. They are a person to two millimeters broad and spaced a person millimeter apart. When the electroceutical material is dry, it functions as an ordinary cloth. But if it receives dampened—say, with saliva, vapor from a coughed up droplet or other bodily fluids—ions in the liquid cause an electrochemical reaction. The silver and zinc then crank out a weak electric subject that zaps pathogens on the floor.

The researchers co-designed the material with the biotechnology business Vomaris Improvements in 2012. Previous 12 months they showed that the technological know-how could be utilised to take care of bacterial biofilms in wounds. A medical demo is underway to more appraise the fabric’s performance as a Food items and Drug Administration–cleared dressing for wound treatment, Sen says.

In reaction to the COVID-19 pandemic, Sen’s group tested its current material on a distinctive coronavirus strain that leads to a respiratory illness in pigs and on an unrelated kind of pathogen referred to as a lentivirus. “We preferred to know how broadly this principle could be applicable,” he says. In a research posted on the preprint server ChemRxiv in Might, Sen’s group reported that its electroceutical cloth destabilized each viruses, leaving them unable to infect cells. The researchers approach to post the success to a peer-reviewed journal as effectively.

To research the fabric’s action, they placed a liquid alternative that contains viral particles on to the electroceutical cloth and a polyester manage cloth without the need of the metal dots. Right after the droplets were being fully absorbed, and the samples had rested for a person to 5 minutes, the researchers recovered viral particles from each materials and tested whether or not they could nonetheless infect the types of cells they commonly goal.

“The knowledge offered here demonstrate that, of the total virus that was recovered, a substantial percentage was inactivated,” says Jeff Karp, a professor of drugs at Brigham and Women’s Clinic in Boston and co-leader of an N95 respirator performing group at the Massachusetts Typical Brigham Centre for COVID Innovation. Karp, who was not included with the research, adds that the researchers did not test all of the virus that they had placed on the cloth. “In point, the bulk of virus was not recovered from the textiles examined in this research,” he says. Sen responds that his group focused on sampling only adequate viral particles to demonstrate that the cloth had rendered them unable to infect cells. The researchers recovered roughly 44 p.c of the particles from the electroceutical cloth samples that had rested for a person moment. And they retrieved 24 p.c of them from the samples that had rested for 5 minutes.

The material’s virus-battling skills have not been tested precisely on SARS-CoV-two, the coronavirus that leads to COVID-19. The researchers’ findings with the two viruses they examined, even so, gave them “hope that this could utilize far more widely,” Sen says. He adds that large-scale manufacturing of the electroceutical cloth is now possible and that the expenditures of making it are comparatively minimal. The metal dots could be printed directly on to the front surfaces of masks, he implies. Or an electroceutical cloth could be inserted in between the front of a mask and the wearer’s face.

If a virus-halting PPE material were being widely obtainable, it could limit the novel coronavirus’s skill to spread. “There is a massive unmet want to much better have an understanding of modes of viral transfer that guide to virus transmission,” Karp says. “As we acquire a much better knowing of this, there is a massive instant want to acquire and rapidly utilize answers that can lessen transmission.”

Steel dots are not the only probable method. Paul Leu, director of an highly developed components laboratory at the College of Pittsburgh, and his colleagues are acquiring a textile coating that repels bodily fluids, proteins and bacteria. It also repels a person strain of adenovirus that leads to respiratory illness and a further that leads to conjunctivitis, as reported in ACS Used Materials & Interfaces in April. Leu’s group has also not tested the material with the novel coronavirus itself, even so. “The major point with testing [the coating on] SARS-CoV-two is the biosafety stage you want to test it, because it’s quite dangerous,” he says. Nonetheless, his group plans to see how effectively textiles with this coating repel a distinctive coronavirus.

Leu says the coating, which remains repellent even just after ultrasonic washing and scraping with a razor blade, could make PPE safer for wearers to get off. It could also be utilised on hospital mattress linens, drapes and waiting home chairs, the researchers note in the research. But Leu details out that the coating is meant for use with healthcare textiles that are now viewed as reusable. His group has not tested it on single-use masks or N95s, but he thinks it could potentially hurt them. Nonetheless, he says, the coating could function effectively for cloth masks these types of as those now remaining worn by a lot of amongst the normal general public.

By acquiring components that kill or repel viruses, researchers hope to make masks and other protecting equipment safer to eliminate and far more helpful in opposition to all viruses. “If the prevalent person were being to have PPE that would not spread infection,” Sen says, “I believe which is a big, big deal.”

Read through far more about the coronavirus outbreak from Scientific American here. And go through coverage from our international network of magazines here.