Could lab-grown plant tissue ease the environmental toll of logging and agriculture? | MIT News

It usually takes a large amount to make a picket table. Mature a tree, slash it down, transport it, mill it … you get the issue. It is a a long time-very long approach. Luis Fernando Velásquez-García suggests a simpler option: “If you want a table, then you must just grow a desk.”

Researchers in Velásquez-García’s group have proposed a way to increase particular plant tissues, this sort of as wood and fiber, in a lab. Continue to in its early stages, the notion is akin in some means to cultured meat — an option to streamline the generation of biomaterials. The staff shown the idea by growing buildings produced of wood-like cells from an initial sample of cells extracted from zinnia leaves.

Though that’s still a lengthy way from rising a table, the operate presents a feasible beginning place for novel approaches to biomaterials generation that ease the environmental burden of forestry and agriculture. “The way we get these components hasn’t transformed in centuries and is extremely inefficient,” says Velásquez-García. “This is a true probability to bypass all that inefficiency.”

The paper will be posted in the Journal of Cleaner Creation. Ashley Beckwith is guide creator and a PhD scholar in mechanical engineering. Coauthors are Beckwith’s co-advisors Velásquez-García, a principal scientist in MIT’s Microsystems engineering Laboratories, and Jeffrey Borenstein, a biomedical engineer at the Charles Stark Draper Laboratory.

Beckwith says she’s usually been fascinated by plants, and inspiration for this undertaking struck when she recently expended time on a farm. She observed a number of inefficiencies inherent to agriculture — some can be managed, like fertilizer draining off fields, even though other individuals are totally out of the farmer’s regulate, like temperature and seasonality. Furthermore, only a fraction of the harvested plant is really made use of for meals or components creation.

“That bought me pondering: Can we be more strategic about what we’re getting out of our system? Can we get much more yield for our inputs?” Beckwith states. “I desired to locate a additional effective way to use land and resources so that we could permit additional arable locations continue being wild, or to remain decreased manufacturing but allow for for greater biodiversity.” So, she brought plant manufacturing into the lab.

The researchers grew wooden-like plant tissue indoors, devoid of soil or daylight. They begun with a zinnia plant, extracting stay cells from its leaves. The team cultured the cells in a liquid expansion medium, permitting them to metabolize and proliferate. Future, they transferred the cells into a gel and “tuned” them, explains Velásquez-García. “Plant cells are comparable to stem cells in the sense that they can grow to be anything at all if they are induced to.”

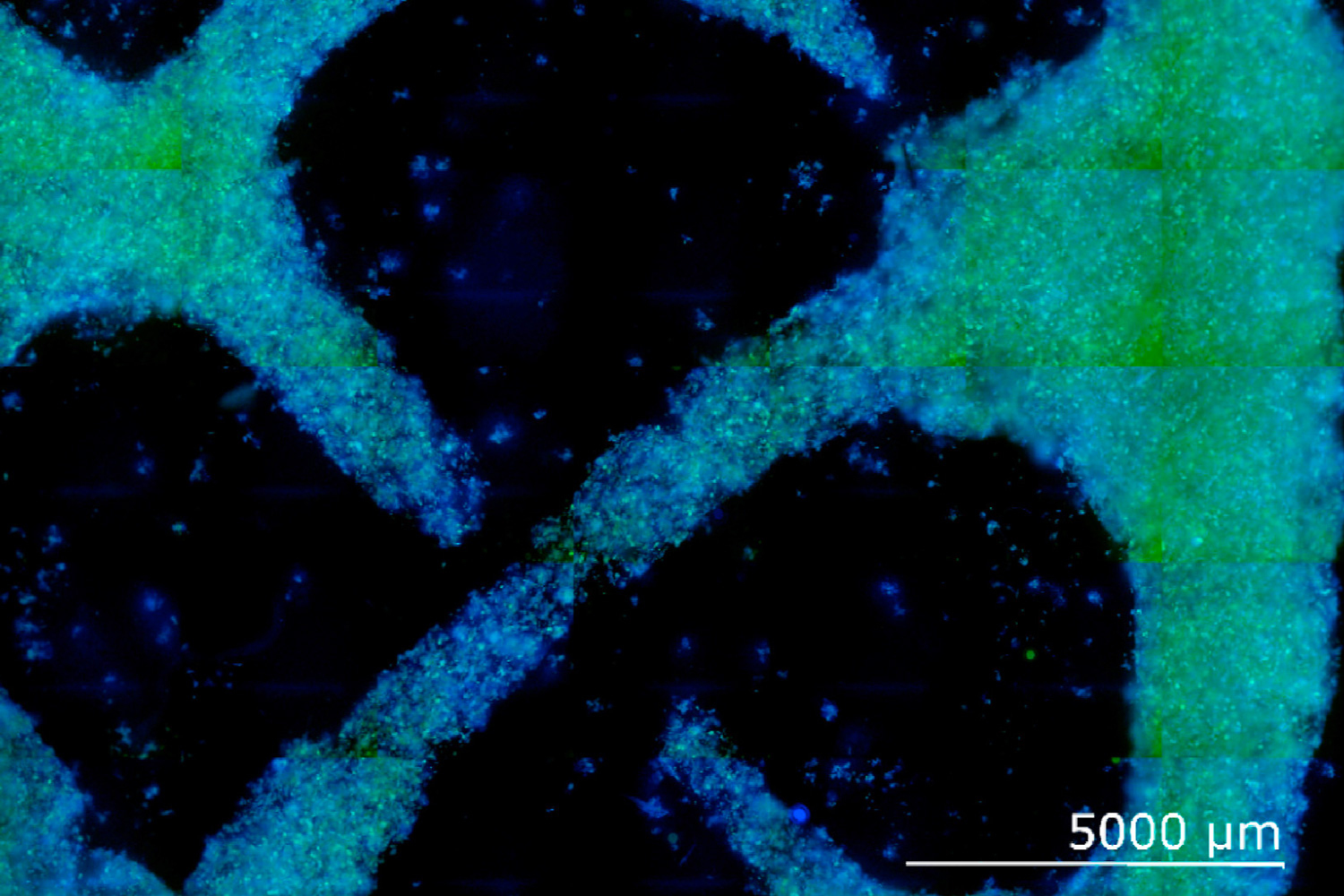

The researchers coaxed the cells to grow a rigid, wood-like structure employing a blend of two plant hormones termed auxin and cytokinin. By different the levels of these hormones in the gel, they controlled the cells’ manufacturing of lignin, an natural polymer that lends wooden its firmness. Beckwith suggests she assessed the cellular composition and composition of the remaining merchandise applying fluorescence microscopy. “You can visually assess which cells are getting lignified, and you can evaluate enlargement and elongation of cells.” This procedure demonstrated that plant cells can be utilized in a managed generation procedure, resulting in a content optimized for a individual function.

Velásquez-García sees this do the job as an extension of his lab’s target on microfabrication and additive manufacturing tactics like 3D printing. In this situation, the plant cells themselves do the printing with the help of the gel advancement medium. As opposed to an unstructured liquid medium, the gel acts as a scaffold for the cells to improve in a specific form. “The notion is not only to tailor the homes of the material, but also to tailor the shape from conception,” states Velásquez-García. Thus, he envisions the possibility of a person working day expanding a desk, no two-by-fours or wood glue vital.

The technology is far from sector-all set. “The concern is no matter if the technologies can scale and be competitive on an economic or lifecycle basis,” claims David Stern, a a plant biologist and President of Boyce Thompson Institute, who was not involved with the study. He provides that scaling up this strategy “would choose important financial and mental expense,” possible from each govt and private sources. Stern also points to tradeoffs in bringing pieces of forestry and agriculture into the lab. “Agriculture makes use of the sun’s strength through photosynthesis, and — apart from in irrigated lands — purely natural rainfall. It does not involve buildings, heat, or artificial light-weight.”

The scientists acknowledge it is even now early days for these lab-developed plant tissues — the team will maintain great-tuning the controls, like hormone amounts and pH of the gel, that give increase to the final material’s qualities. “It is really uncharted territory,” claims Velásquez-García. “One pending question is: How do we translate this good results to other plant species? It would be naïve to feel we can do the very same matter for each and every species. Perhaps they have distinctive command knobs.”

Beckwith also anticipates difficulties in increasing plant tissues at significant scales, these kinds of as facilitating fuel trade to the cells. The crew hopes to defeat these boundaries by way of even further experimentation and sooner or later establish generation blueprints for lab-grown products and solutions, from wood to fibers.

It’s a radical but sophisticated vision — “a new paradigm,” according to Borenstein. “There’s an opportunity right here to consider developments in microfabrication and additive manufacturing systems, and use them to address some actually significant issues in the agriculture arena.”

This research was funded, in section, by the Draper Fellow Software.