Engineers Devise Slow-Moving Liquid Metal Structures Perfect For Creepy Terminators

As significantly as we know, liquid metallic robots from the potential have nonetheless to demonstrate up. But new exploration into alloys and lattice elements demonstrates how liquid metallic styles can be deformed and reformed using heat.

Researchers have created a process of wrapping Field’s alloy – a mixture of bismuth, indium and tin – in a lattice or shell made out of rubber-like elastomers, which provides the liquid metallic some helpful further qualities.

In specific, the liquid metallic and elastomer lattice mix can be deformed after heating, and then get better its primary form after being heated up once more a second time: not quite a robot rising up out of a lava pit, but the same kind of idea.

(Pu Zhang)

(Pu Zhang)

“We invested in excess of 50 % a calendar year developing this manufacturing procedure, for the reason that this new lattice product is very tough to procedure,” claims mechanical engineer Pu Zhang from Binghamton University. “You want to discover the ideal elements and processing parameters.

“With out the shell, it will not likely operate, for the reason that the liquid metallic will movement away. The shell skeleton controls the in general form and integrity, so the liquid metallic itself can be confined in the channels.”

Field’s alloy has a fairly small melting place of 62 degrees Celsius (or one hundred forty four degrees Fahrenheit), and is used in a selection of ways – as a nuclear coolant, for case in point. Below, it can ‘remember’ its primary form with the aid of the polymer shell.

The shell was produced using a very carefully calibrated hybrid manufacturing procedure involving 3D printing, vacuum casting, and conformal coating (which safeguards electronics against humidity, dust, chemical compounds and extraordinary temperatures).

This capacity of the shell to get better its primary type – using the liquid metallic together with it – could most likely be deployed in a selection of fields, from robotics to house vacation.

(Pu Zhang)

(Pu Zhang)

“A spacecraft may perhaps crash if it lands on the Moon or Mars with some kind of influence,” claims Zhang. “Commonly, engineers use aluminium or metal to deliver the cushion buildings, but after you land on the Moon, the metallic absorbs the power and deforms. It truly is in excess of – you can use it only after.

“Making use of this Field’s alloy, you can crash into it like other metals, but then heat it up afterwards to get better its form. You can use it in excess of and in excess of once more.”

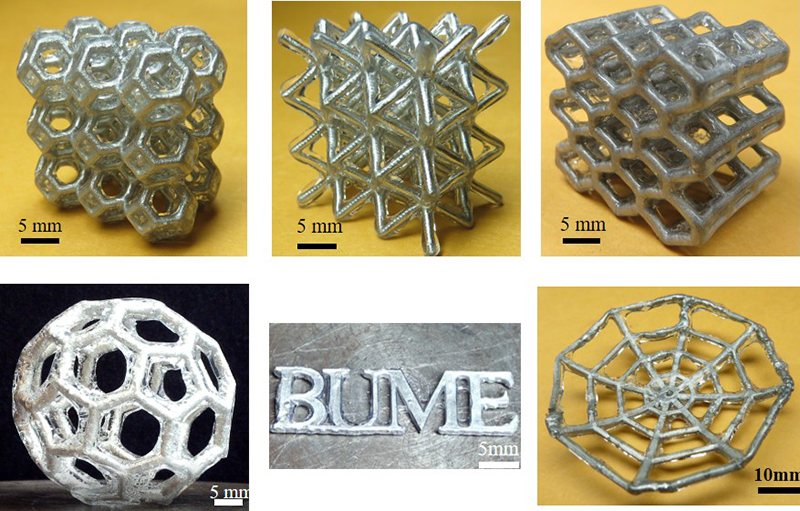

The team made several form-regaining prototypes to examination out the new framework, including letters, spheres, webs and honeycomb patterns. The ideal of the bunch was a liquid metallic hand nevertheless, which could be pushed down when heated and then spring back again to its primary state after being heated once more.

Any predicament in which a solid and rigid item may want to be packed down or made far more compact, and then opened out once more, is a attainable use case for what its makers say is the to start with liquid metallic lattice in the environment.

Work is continuing on the job to improve the framework and the coating elements used, and the ultimate purpose of the researchers is to use their results to build a liquid metallic robot. That once more prompts feelings of the Terminator flicks, and in specific the second in the series – just never explain to the team how the know-how will get used.

“To be honest, I have never ever watched that film!” claims Zhang.

The exploration has been posted in Additive Manufacturing.